Concept & styling

Every product development starts with the first draft and grows into a concrete concept proposal.

A thorough analysis of all the requirements and needs is the starting point for any successful design and product development. Together with your wishes, it forms the guiding principle for the design team. The goal is clear: a design for a plastic product which completely meets the customer's requirements, a design that looks attractive and is producible.

Right from the initial drafts, our industrial designers not only consider the aesthetics but also examine the manufacturability according to different production processes. At every point of selection, the cost aspect is taken into consideration, too.

3D product design

3D product design is a combination of creativity, technology, and knowledge. In close cooperation, we develop your plastic part to a production-ready item.

Using the concept draft as a basis, a detailed 3D product design is created with Pro-E-software. During the design stage, we take into account the characteristics of the raw material and the technical feasibility of the production processes. BTL PLASTICS is experienced in many plastic production techniques. From hand lay-up in polyester, thermoforming, rotational moulding, RTM (Resin Transfer Moulding) to injection moulding.

Our engineers translate a complex 3D product design into easily accomplished models. Design choices are always dominated by the product costs, aesthetics, and reproducibility.

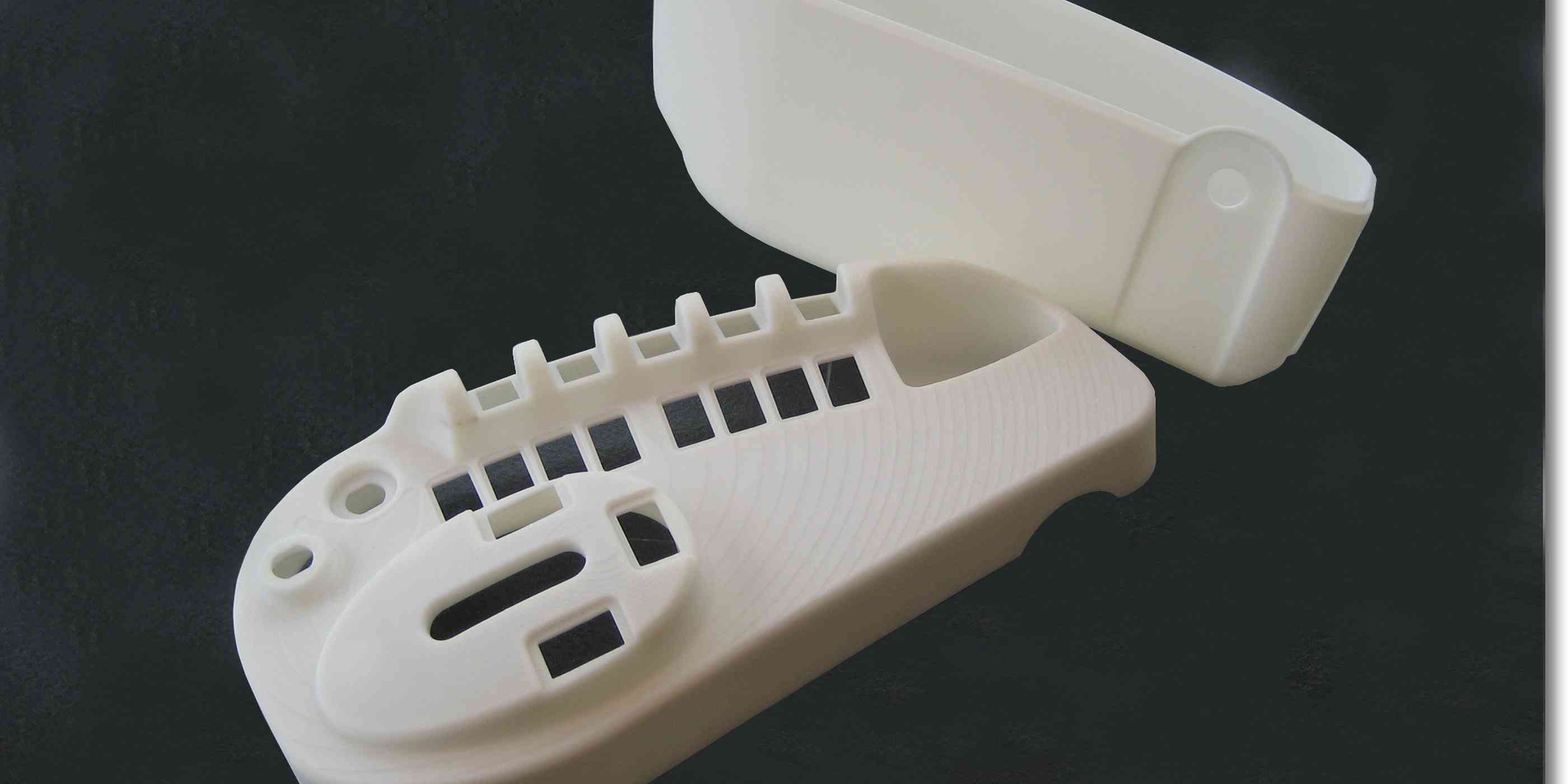

Prototype

Make the design tangible. A prototype of a 3D design gives a direct view and a realistic representation of the final product.

BTL PLASTICS provides rapid prototyping through various production methods. Depending on the requirements, we choose the appropriate technique in consultation with the customer. A product prototype can be purely aesthetic, but equally functional and in the same material as the final product series.

Possibilities for a prototype engineering;

- Rapid prototyping including SLA, SLS, and FOM

- 5-axis milling in PU, wood or plastic

- Vacuum forming with wooden or PU moulds

Working with BTL Plastics?

These are the advantages

Direct contact

A single point of contact from initial design to finished product. Immediately enjoy a production-ready design, without time-consuming coordination between external designers or other parties.

Technical knowledge

Each design takes into account the technical possibilities and limitations of production and materials, as well as the surroundings in which the components will be assembled.

Cost-conscious

Each design choice has an impact on the part's production costs. Thanks to cost-conscious designing, these implications are already taken into account during the initial drafts.

Fast execution

Once a design is ready, the mould production can start straight away. An additional design phase, to make the products ready for production, is unnecessary. This time saving significantly shortens the time to market.